Software

A Cornerstone of our Success

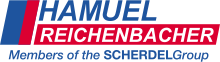

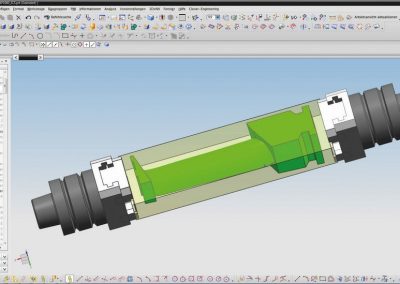

An optimum interaction between the machine and the specifically established CAD/CAM-software is of great significance for the production of turbine blades. Our software is based on renowned CAD/CAM-systems. However, we have integrated additional important features to considerably enhance the manufacturing process for you, as well as the work-part programming. This means that you will definitely benefit from a reduction in programming time of up to 45 per cent, and sometimes reduce machining time even by one half, when using this software correctly.

At a glance

Your Advantages

- The software includes special patent protected machining techniques to obtain the maximum removal of material while ensuring the greatest precision.

- A CAD/CAM-solution for the simultaneous 5‑axes high-speed machining of turbine blades.

- The programme efficiently shortens the generation of tool paths for the milling machine.

- Roughing out strategies with spiral cutting of blade profiles, head and root transition areas and grooves.

- Finishing strategies with spiral milling and combined tilt and swivel angle movement, Z‑constant machining, milling with point or flank contact, and milling of head and root areas.

- Integrated post processors for the HSTM-series.

- Optimum integration into the customer CAD/CAM-structure by add-in software feature.

- Superior milling technology and strategy for turbine blades.

- Automated and the shortest programming possible.