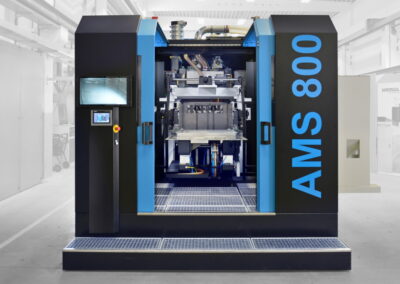

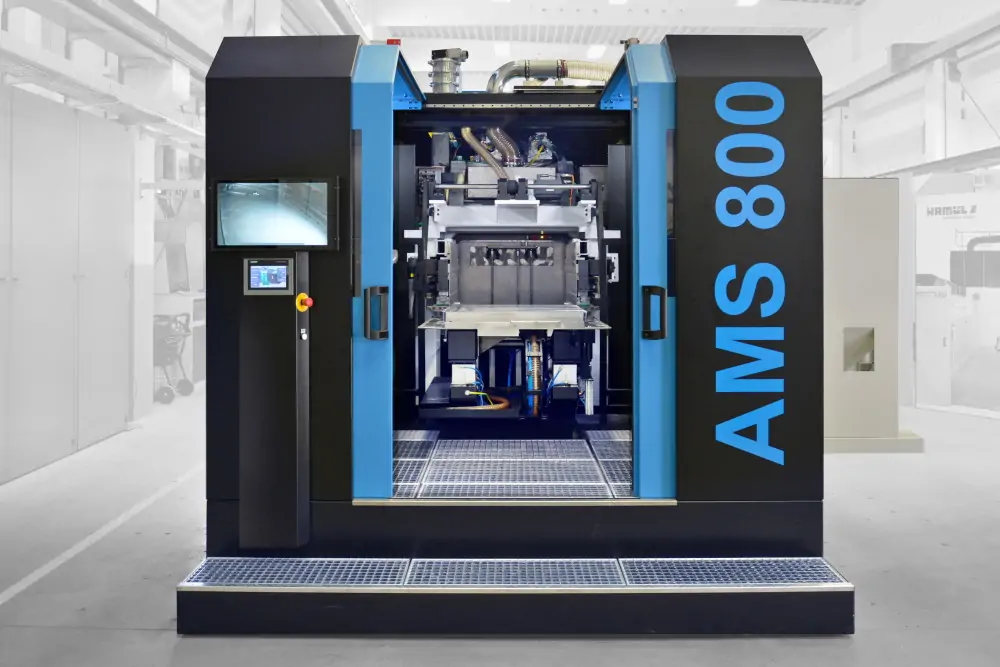

AMS 800

Selective laser melting

The AMS 800 was developed for the powder bedding process and further processing by laser melting (LM) and is particularly suitable for the production of large-volume metal components.

Here, we offer a unique solution on an industrial scale, especially when it comes to large building volumes, some of which are impossible to realize in the conventional way.

The integrated powder preparation and inert gas system (nitrogen N2) places great emphasis on sustainability and safety. The handling of the components takes place outside the building area and the transfer between the machining processes is fully automatic. The aim was to create an open system where it is possible to configure the equipment for various CAD/CAM interfaces and machine control versions. Thus, the customer decides which R&D project he wants to carry out.

Dr. Kawalla-Nam: „This trendsetting technology opens the doors to completely new manufacturing and design concepts, as many of the processes currently available are still too expensive or too slow for the industry.“

Control system (Siemens make)

Open system for various CAD/CAM interfaces and machine control versions. The customer decides which R&D project he wants to carry out.

In the cleaning cabin, the operator can remove the remaining loose powder by suction. The build-plate can be loaded into the machine using a crane.

Handling

An innovative handling system automatically transfers the build-plate from the discharge station into the process chamber.

Extraction system

Fume extraction system (filtration) with a sinter-plate filter in combination with safe passivation and integration into the inert gas circulation system.

Nitrogen generator

The nitrogen generator permits the creation of the inert gas atmosphere with a nitrogen purity of up to 99.9%.