Component Manufacturing

Tailor-made solutions

Component production at HAMUEL also follows the highest standards. Innovative production techniques, state-of-the-art machines and qualified employees produce premium quality from the smallest to the largest component.

Mechanical Engineering OEM Solutions

Machine construction and assembly

HAMUEL has several decades of experience in manufacturing structural parts, components and assemblies for machine tools construction. HAMUEL’S machine tool customers can also benefit from this specialist know-how.

As a consequence, HAMUEL develops, produces and assembles for several very renowned machine tool manufacturers everything from structural parts up to entire finished machines. Of course, in this context great importance is attached to the utmost quality standards. HAMUEL customers can get everything from one source: sheet metal work, welded parts and machined components, as well as the finished machine.

The assembly and installation of a machine requires a very well-trained and instructed staff. HAMUEL will build and install your machine based on their longstanding experience. Upon request, our design department will even develop the latter in co-operation with your company.

In case of final assembly capacity shortage at your company, we would be pleased to demonstrate our flexibility and offer the assistance of our assembly bay to complete the final fitting of your machined or fabricated elements, for delivery back to your plant. Our proven experience with an impressive list of customers using this service shows that we will merit your trust every time.

Laser Cutting and Bending

Welding Technology and Component Manufacturing

In Plauen demanding sheet-metal, formed and welded components are manufactured based on a combination of the most modern laser-cutting and bending technology. Drawings provided by the customer are immediately taken on and adapted to these manufacturing processes. Thus, starting with a lot size of just one part the economic production of components or assemblies exactly to customer requirements will be possible.

Moreover, welded parts up to a piece weight of 25 tonnes and a length of 15 metres can be made in Plauen.

- Welded steel constructions up to 25 tonnes

- Certified per DIN EN ISO 3834–2:2021

- Certified specialist for environmental protection

- Contract manufacture: Laser- and flame cutting, bending, tempering, blasting and priming

Optimum Solutions

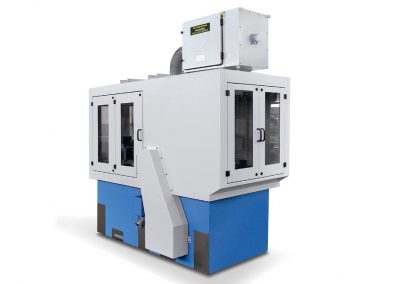

Machining

HAMUEL has decades of experience in manufacturing high-precision and intricate components. Thanks to their well-equipped machining department which incorporates everything required, from milling, turning and grinding, up to the inspection measuring technology necessary in these fields, HAMUEL is your reliable partner for the machining of many precision components.

Technological progress makes ever increasing performance demands on the components used today. This brings about advanced special materials and alloys with very good specific technological properties to meet these needs. However, the economic machining of these materials that are optimized for their applications also gets ever more complicated.

The great know-how of the HAMUEL application engineers and the outstanding flexibility and capability of our machines enables us to find the optimum solution for your difficult machining task. We render the impossible possible.