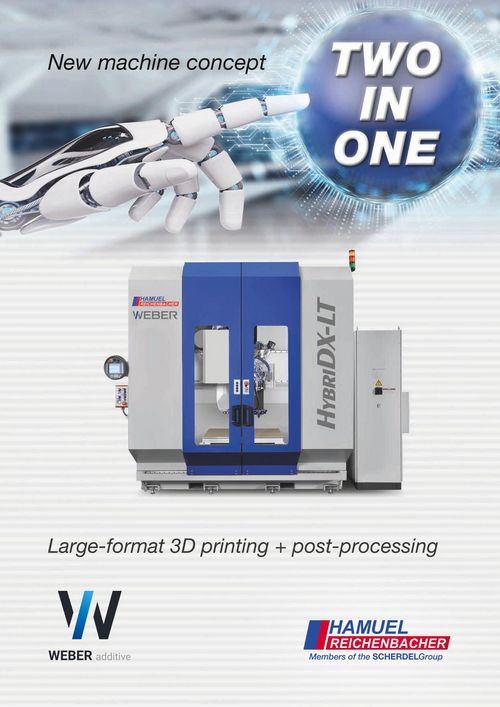

HybriDX-LT

Hybrid manufacturing technologies

In the hybrid manufacturing of thermoplastics, the ECO-Hybrid combines fused granular fabrication (FGF)-based extrusion with machining.

This plant, which has been developed in cooperation with the Additive Manufacturing Systems Division of Hans Weber Maschinenfabrik GmbH, is based on the direct extrusion of a plastic granulate. The continuous additive printing process permits the production of large-volume and extremely resilient components. After or during printing, 5‑axis machining takes place to optimise accuracies and surfaces. This makes the system an ideal choice for the production of rough-shaped components for use as quick prototypes or for the final production of small and large series.

Dr. Kawalla-Nam: „This trend-setting hybrid technology renders processes much more efficient. The goal must be to produce large quantities in a short time at competitive costs.“

In addition to small 3D components, the ECO-Hybrid mainly permits the fast production of large-volume components, such as façade elements, formwork for the construction industry or casting/pressing moulds in mould-making industries. CNC machining perfects their functionality in terms of desired accuracies and high-quality surface finishes.

HybriDX-LT

ECO-LT basic machine: Low-vibration portal frame with stationary machining table on a stable substructure. A protective cabin including ceiling element encloses the machine completely. Two versions of equipping the unit and a tool changer with 7 places satisfy most diverse customer requirements.

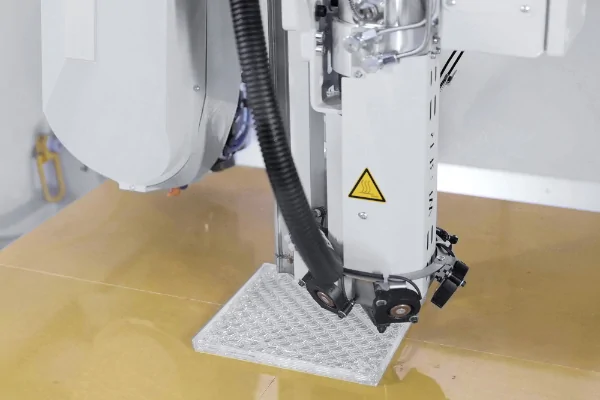

Printing table:

- Table surface heatable up to 150 °C

- Permanent printing plate (surface)

- Base plate from cast aluminium

- Plate milled (level or with grooves)

- Steel bars with fitted and threaded bushes

Extruder

Plasticising up to 450 °C

Maximum material output from 8 kg/h to 30 kg/h

Nozzle diameter from 1 mm to 20 mm

Subsequent to their fusing in the extruder, a nozzle deposits the fused pellets on the build-plate/printing table in layers.

Milling unit

The cardanic 5‑axis working head provides for an undercut of up to 46° and can be equipped with different head versions. This permits the high-precision three-dimensional machining of free-form surfaces and contours during and after 3D printing.

Time-lapse video: 3D printing + post-processing

Concrete applications for 3D printing

Machine brochure

Industry brochure

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.